Schuy + Folmeg Maschinenbau GmbH … Ihr Partner rund um Abfüll- und Verpackungsanlagen

SCHUY + Folmeg ist Ihr Partner rund um Abfüll- und Verpackungsanlagen sowohl für die Lebensmittel- als auch die Non-Food-Branche.

Durch eine stark kundenfokussierte Struktur im Unternehmen können wir Ihre Bedürfnisse und Anforderungen zielgerichtet in Ihren Maschinen für Ihren Erfolg umsetzen.

Wir stellen uns gerne den Herausforderungen, die Sie uns zur Aufgabe machen. Dadurch haben wir in den letzten Jahrzehnten sehr viele interessante Projekte umsetzen dürfen.

Durch eine stark kundenfokussierte Struktur im Unternehmen können wir Ihre Bedürfnisse und Anforderungen zielgerichtet in Ihren Maschinen für Ihren Erfolg umsetzen.

Wir stellen uns gerne den Herausforderungen, die Sie uns zur Aufgabe machen. Dadurch haben wir in den letzten Jahrzehnten sehr viele interessante Projekte umsetzen dürfen.

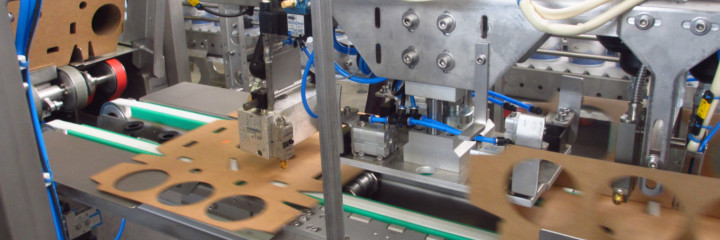

Projektvorstellung: Maschine CC 50 „Sonnenschutzaufleger“ zur Aufbringung eines Sonnenschutzes auf dem Bierkasten

Das Ziel dieses Projektes war es, bedruckte Zuschnitte, die als Sonnenschutz dienen, auf Bierkästen aufzuspenden und diese dann unter die Kronkorken der 4 Eckflaschen anzudrücken. Dazu werden die Zuschnitte aus einem Magazin geschuppt in eine Auflegeeinheit gespendet. Diese setzt den Sonnenschutz auf der Kasten auf und anschließend wird dieser mit einer Andrückeinheit unter die Kronkorken angedrückt. Unsere hochflexible Anpassung an Kundenwünsche eröffnet Spiel-raum für besondere Maschinen.

+49 (0) 1590/ 418 89 60

+49 (0) 1590/ 418 89 60